So this season has had many ups and unfortunately many downs too.

Some background on my setup.

I'm running Massive's street kit, the 280x22 setup with Meyle blanks that 2002maniac so graciously supplies (since there aren't many other alternatives). I am also running a 7 series master cylinder.

Ever since I started using this setup I noticed that I'd burn through a set of pads in one day no problem. Previously it was dependent on the track... this season not so much. I would run the pads all the way down to their backing plate without issue but still... one track day?! I tried PFC 01's, HT-10's, ST-41's (just tried these), and Wilwood Compound H's up front. None of these lasted me more than one day.

For reference I've been to: Lightning, Watkins Glen, Summit Pt Main, Shenandoah, LRP and Thunderbolt.

My last event at Lightning I experienced severe juddering under heavy braking. Pedal stayed nice and firm though. Also, my rotors were glowing red, almost like a proper race car...

After the event I inspected the rotor and noticed that there was heavy grooving... a friend suggested it might be air trapped in the system causing this. Curious what you guys think about this as well.

Front brake temps exceeded 600F and rears were around 200-300 range. Oh and I removed the front backing plates to help with cooling...

So I was at Thunderbolt yesterday and I took the precautionary measure of replacing the seals on my Wilwood calipers. I thought that after about 17 days of track use on em, it was time to replace them. Fairly simple on these calipers so why not? Anyway, after about 20 min of lapping the pedal would start to drop to the floor, a quick pump and I'd have pedal pressure again. I pitted, bleed the system and then went back out... again, after 20 min (or less) the same symptoms would come up. I did this three times and just got fed up with constantly having to bleed the system in order to get a 20 min sessionOne last observation. I hit ABS a few times while braking and soon thereafter the pedal would start to act funny. Air still in the system??

Front rotor temps were above 600 but the rears this time were around 420-440. I ran ST-41 pads up front and PFC 01's in the back.

I don't know what to do at this point... If I go with a larger caliper up front I will most certainly have to get something for the rear. The question is, does it make sense to go that route?

I'm debating whether or not I should consider sourcing e30 m3 5 lug components (almost impossible but time is on my side) or get the E36 M3 stuff up front and something decent in the back (m coupe, 318ti?).

No one at the track has these problems... its driving me mad having to constantly worry about this shit when I'm out there on the track. When the brakes work its great, but when they don't I lose confidence in the car.

So what say you fellow track heads?

Did you clean off those rotors and/or sand down your pads just to make consistent contact patches? Not saying you always have to but is there a chance that could have played a part?

You say your temps are above 600F...but do you know how much above (are you saying its less than 700 but above 600?) are you guessing based off a temp paint chart on the caliper? Or IR gun?

It would make sense you're blowing through pads as you need to get the optimal pad for your temp range. For example, PFC 01s optimal range is around 850-1000F IIRC. So to get ideal braking with least pad/rotor wear, you aren't quite hot enough to be in that range. Do you know what the optimal operating range is for the raybestos pads?

How much does your car weigh? You shouldn't be blowing through anywhere near a full set of pads in 1 track day, there is definitely something not right.

Last edited by M Dizzle; 11-13-2012 at 12:26 PM.

your cooking you brakes.

I would assume the first picture was taken the day you were experiencing problems. I can undoubtedly say.... your brake rotors are WELL over the 600degree mark.

Ducting.

larger rotor.

brake less.

Any combination of the three.

Street kits are for .... well.... the street. With heavy tracking you might want to consider the 300x32.

Last edited by jason89i; 11-13-2012 at 12:43 PM.

+1 I would try brake ducting. And it sounds like you still have air in your lines after rebuilding your calipers. Do you swap the pads out for street pads between track days? Not properly beding your pads could lead to rapid wear.

Maybe I can help shed some light. From your pictures, as well as from the temps you took, it looks like the front brakes do too much work compared to the rear ones. Therefore you could remove the fixed bias valve and fit an adjustable one to help spead the load between front and rear.

To any tracker using this small kit, I have suggested using Wilwood's H compound. A long lasting endurance pad with flat torque, very high friction and smooth to the rotors.

That being said, that entry kit is called "Street kit". It uses small discs, small and thin pads. Perhaps you are asking too much from it. It was not designed to handle that type of abuse. ;-)

1969 2002 racecar + 1989 e30 M3 racecar

Hey man. I bought brand new rotors for yesterdays event and brand new pads. I bedded them in before heading out to the track and I actually drove with them already mounted.

I was using an IR gun but the damn thing only reads up to 605F (I had completely overlooked that detail when I bought it)... funny thing is after 605F the thing says "OK." I stood there in disbelief asking WTF do you mean OK? OK what? OK you're done? Several have recommended paint that reads temps or stickers of some sort. I'm not sure where to get this stuff. I haven't had the car weighed but I figure it weighs anywhere from 2700-2800 lbs it being a 318iS originally.

I'm leaning towards ducting since removing the backing plates did not help tooo much. A larger rotor means going up in size with the caliper etc. That also means doing something about the rear because the bias will probably shift to the front even more so.

Braking less is an option but how do you do that on a track like WGI? Doesn't make sense to just let off early before bus stop or the main straight. Some sections just require hard braking.

That seems to be the case, I used the Motive bleeder. Maybe that thing sucks and I should stick with the 2 man method? I do swap out the pads for street pads in between track days. I'm confident that I bedded them in properly though. I've done the same procedure on other cars and they have not had any problems in that respect.

Yup. That is also the next step. Can I just simply remove it and tie the lines together or is an adjustable one mandatory? What do you use?

I used the H compound at Lightning and the pic I posted above with the rotors glowing red is with that pad. Again, something is definitely not right with my setup so the pad itself may be very good but I definitely cooked them when I was there.

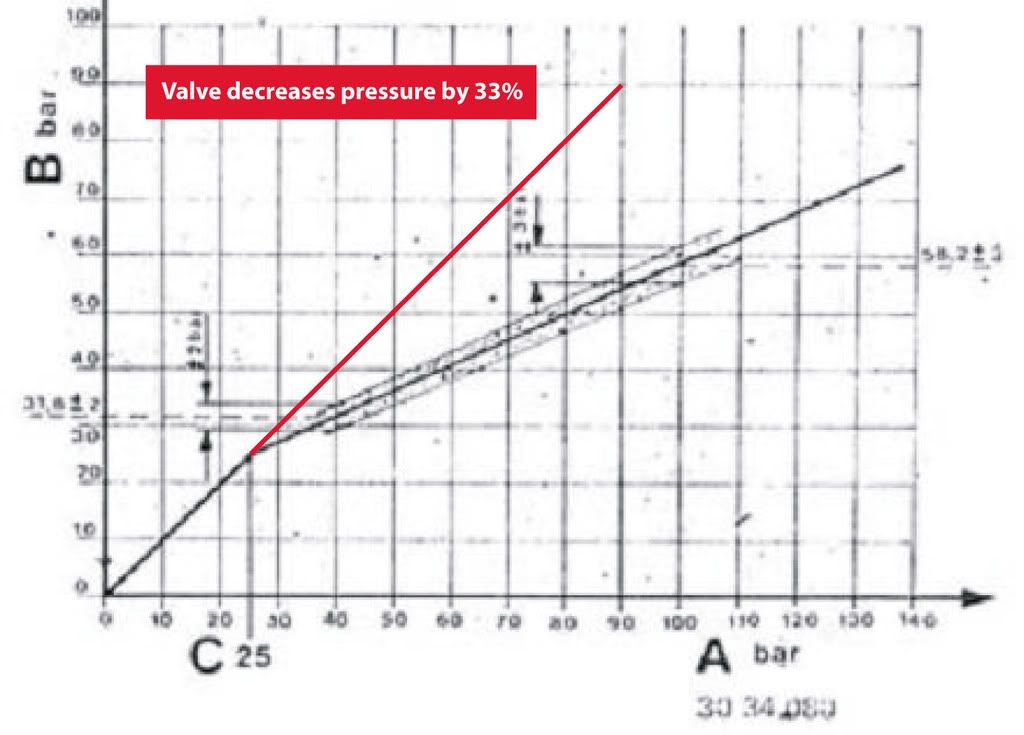

Let's discuss the pervert after-effect of swapping a stock MC with differential bore (22mm fr /17mm rr) to a (usually) bigger one with same size bore. Which results in a major reduction in rear bias (smaller bore in the MC results in higher torque at the caliper while bigger piston means less torque).

Basically going to an MC with same size pistons reduces rear pressure by a hefty 40%, which corresponds to the maximum reduction in pressure from the fixed bias valve.

Last edited by Massive Lee; 11-13-2012 at 02:00 PM.

1969 2002 racecar + 1989 e30 M3 racecar

It is an e30 fer chrissakes. You slow it down by throwing it sideways. The middle pedal is only for getting it off the trailer.

#54 GTS-3/CM E30 Race car

90 Porsche 964 C2 Daily driver

05 BMW 325XiT Kid hauler

04 Chevy 2500HD Duramax

Perpetual hopeless, unfinished projects

What kind of MC would you run for this kind of application then? I have the 7 series variant which is 25mm... but I actually haven't the slightest clue as to what the rear is.

Any recommendations on the adjustable valve? I have never seen anything like it before. Would something like this work:

https://www.pegasusautoracing.com/pr...asp?RecID=9833

The 7 serie MC is equal bores 25.4mm.

You can remove the bias valve and replace it with a Tilton unit with metric fittings. https://www.pegasusautoracing.com/pr...asp?RecID=4889 or use the one you mentionned and fit brass adapters.

1969 2002 racecar + 1989 e30 M3 racecar

LOL. One day when I've actually got the skills to carry her throw a corner sideways... maybe.

Awesome. I was looking at that piece as well.

From the looks of it, the general consensus is:

A. Get ducting

B. Get the bias valve

C. Get a more accurate measure of brake temps

D. Source a better rotor

With the rear end basically doing only half its job, you are overlaoding the front brakes. Fix that and that will be a great step.

1969 2002 racecar + 1989 e30 M3 racecar

Genesis Technologies' Brake Temperature Paint is the best I've found. Available here: http://www.hrpworld.com/index.cfm?fo...action=product. I'd use this anytime I was making significant brake system changes or had an unresolved issue where knowing temps would be useful. Remember to get the temperature range for the pads you use so you can map the rotor temperature onto it.

Lee mentions an appropriate part in his post. https://www.pegasusautoracing.com/pr...asp?RecID=4889

Thanks man, appreciate your help with this... ongoing issue lol. Hopefully next season I will be posting about the improved longevity of my pads and decreased temps!!!!

Thank you sir! I can see the application of it too (wasn't sure where I'd have to paint this stuff).

Last edited by dude8383; 11-13-2012 at 06:03 PM.

Temp paint here...http://www.shopmmw.com/index.php?mai...oducts_id=4689

Otherwise this is what we use...http://www.shopmmw.com/index.php?mai...oducts_id=9327

The pyrometer is great for brakes and it helps with set-up in regard to tire temps, ect.

-Ryan

Last edited by noodlexyz; 11-13-2012 at 06:13 PM.

1993 325is racing car type thing....

@dude8383 - The other simple solution is to put the original 22/17 MC back. ;-)

1969 2002 racecar + 1989 e30 M3 racecar

Here's what the fixed e30 bias valve does. Starting at 25bar, the progression of the pressure on the rear circuit stops being linear with the front progression. Removing the valve means both circuits will increase in pressure linearly. Then, adding an adjustable valve will allow to fine tune the location of the knee, and therefore the distribution to the rear hydraulic circuit.

1969 2002 racecar + 1989 e30 M3 racecar

you are overlaoding the front brakes. Fix that and that will be a great step.

So you put the proportioning valve in the rear line only?

Sure its a silly question, but I am just verifying.

Just a point of reference: I had great luck with my z3 M Coupe setup (f/r) on my e30s50. My car weighed in at 2695 with me in it and a full interior. After I swapped to the bigger brakes and wheels (235/40/17 R1's) I didn't have a single issue with the brakes even with no ducting. I wasn't exactly easy on the car either

Gosh. That is interesting to say the least. I ran a set of PFC06 front and rear on my 87 325iS at Road Atlanta. I ran 2 weekends and instructed another weekend. I took them off and donated to my friend. Going to run PFC08. Want to try out the new compound. I had zero issues with destroying the brakes.

OBD1 M52 w/ S52 Cams

6 Speed

3.73S

OEM Brakes

E34 V8 Master

Bookmarks