Hello everybody,

I am not new to the forum but a bit of a lurker in this area specifically. Some of you may be familiar with my car, it is an SCCA DSP class prepared autocross car that I have been competing with in the past few years. One of my favourite events of the year in our Pacific Northwest calendar is the Knox Mountain Hillclimb in Kelowna, BC. My car has been fun to run up the hill but since the DSP class is so limiting, the car isnt really that fast in an event that is so power-to-weight dominated.

This is my 2010 run, a 2:04 which is a personal best for me. The quality is a bit better if you watch it in Youtube:

[ame]http://www.youtube.com/watch?v=4HOSyjVzRgo[/ame]

My car at the end of the 2010 racing season after an SCCA National Tour win in Packwood, WA:

Terry and the crew at Vorshlag have been great to me over the past few years and I have been customers of theirs for awhile now and have always looked on with awe at their LS1 projects and dreamed "what if..." but the situation never seemed right. Well, this winter, the situation seemed about as right as it would ever be and after some substantial soul searching... I just decided to jump in with two feet! The goal is to build a no compromise to-the-limit (of my wallet) hillclimb car that I will run in hillclimb, time attack, and autocross events with an LSx drivetrain.

Starting out...

After phase 1... race weight for me in DSP trim was approximately 2880lbs including fuel and rollbar, but no driver, already a substantial savings!

Glory

Drivetrain out:

Obligatory no drivetrain scale shot:

Some new arrivals to the garage:

My original plan called for a T56 so I could use all of Vorshlag's off the shelf parts... mounts, driveshaft, etc. However, I couldnt find a deal on one locally and then somebody left me alone with Ebay and a credit card...

Not a cheap, sensible, easy to work with T56 transmission

EDIT - it appears the Ebay link is down now, so here's a teaser:

Although this transmission is going to require some engineering to get into the car, it should be great when it's done, it is a Jerico 4spd race dogbox that is a standard item in many GT cars and is considerably lighter and stronger than a T56, although I dont expect I would have ever broken a T56 with the modest power levels I am looking for.

Last edited by lowside67; 03-01-2011 at 08:43 PM.

More glory!

looking forward to progression!

-Matt

99' techno e36 M3 coupe/5sp

Wow, straight-cut gears and dog clutches --- be careful, homie!

E30-LS1 Swap Guide and Kits, email us at e30ls1@gmail.com !!! or check our website e30ls1.wordpress.com

You know it! In the past I've always run just a rollbar, 6pt harnesses, and fixed back race seats and felt reasonably comfortable. However, the eventual goal for this car is 450rwhp and 2350lbs so there is no doubt that it will be a rocket, and with that in mind, it was time to get a full cage. Along with the safety aspect of the rollcage, I had a few goals in mind - integrate the front strut towers as best I could with the V8 going in, add a 3rd jacking point on each side of the car, brace the rear subframe points, and cut out all the stock fuel tank/rear seat area and replace with aluminum and a fuel cell in the trunk.

I have lots of photos of the cage in progress but I figure for the sake of not cluttering up this thread, I will just post a few of the "finished" product:

Moment of truth time... how much did it weigh? Before it left, it weighed in at 1643lbs - this total included driver's side seat mount, battery, some odds and ends, and 3/4 tank of fuel (approx 40L). According to the interwebs, 40L of fuel is approximately 60lbs. It also still had the complete factory braking system including ABS unit and master cylinder.

The new weight is without any fuel in the new cell and with no brake lines or master, etc still on (this is a hint as to what comes next!):

1567lbs!!! When we first saw this, we went... err, WTF. We thought we must have forgotten to zero the scales. Lift it up, zero the scales, set it back down again... 1567lbs again. Then we started going through the car and it started to make sense... no fuel, no stock fuel tank, no wiper motor (will be going back in after paint), no master cylinders or pedals, etc. However, while there are still a few odds and ends to come out and not THAT many things to put back in, I think it's safe to say at this point that the car will reach its goal of 2400lbs ready to race.

The car is ready for a healthy POR-15 bath!

Last edited by lowside67; 03-02-2011 at 01:26 AM.

Sweet, sweet separation

At some point along the way, another "well, it's only money, so...." decision got made, and the result was:

Of course along with that comes:

Final cockpit view with setback pedals and column. The pedals have been moved back approximately 6" over stock so that my midget-like proportions can move rearward in the car to improve weight bias and also so I have more room to see out the window, get out the window, etc.

Some new toys are starting to arrive:

First up is the dash/datalogger. I chose the Racepak IQ3 as it is a bit cheaper than some of the alternatives (ie the AIM MXL Pista) and the software seems to be well liked and compatible with the common Racepak G2X datalogger.

The display unit (this unit is an entirely self contained unit except sensors with integrated GPS and 32 channel datalogging along with the display):

The universal sensor module that will allow me to use cheap standard 5V sensors rather than the Racepak specific sensors, along with 2 temp sensors and some miscellaneous connectors:

Next, thanks to Frank at Driver's Edge Autosport, our club's sponsor, the Tilton 600 series pedal set (currently without any master cylinders):

And finally the aluminum remote brake bias adjuster:

Lots of other stuff has showed up but not photographed... all of the parts for the transmission are now here - bellhousing, release bearing, clutch, flywheel, etc. Also just got tracking numbers from Vorshlag so headers and mounts are enroute!!!

really interested to see how the turn1 pump feels with an e36 steering rack - what rack are you intending on running? an e36, a z3 or an e46 330zhp?

I have a z3 1.9 rack going in the car, I will report back!

Last edited by lowside67; 03-02-2011 at 02:31 AM.

I was waiting for this thread - we already knew that you were swapping...

I think you will be happy with that steering rack choice. I run it and I like it very much (especially with a 330mm steering wheel).

Matt Nucci

6/94 E36 M3 Cosmos CP

wow! nice

Looks good

Rob

Prior projects:

1998 540i with 6.6 LS2/T56 Chevy Power

- pictures and details

1992 325i with 6.6 LS2/T56 Chevy power - pictures and details

1995 M3 with 6.6 LS2/T56 Chevy power - pictures and details

Thanks for all the words of encouragement guys! I have a quick question... obviously there is no off the shelf transmission crossmember or driveshaft for my Jerico combination, what is the best way to measure the "height" of the crossmember I need to build to set the output shaft at so that it is in line with the diff?

The best way to do it is to put it in the car and then measure.

Rob

Prior projects:

1998 540i with 6.6 LS2/T56 Chevy Power

- pictures and details

1992 325i with 6.6 LS2/T56 Chevy power - pictures and details

1995 M3 with 6.6 LS2/T56 Chevy power - pictures and details

I understand that but what exactly am I measuring? Since I will only have engine mounts, not transmission mounts, the transmission output shaft will be able to move up and down quite a bit, what I am asking is where should I be measuring to ensure the driveshaft is as straight as possible.

What you need to measure for is the pinion angle. If you ask 10 people how to do this you will get 10 different answers. Since you will be seeing some high speeds this measurement is critical for a vibration free and safe drivetrain.

This is how I measure mine and have zero vibration.

Got the car on jack stands and put in my engine and trans made sure it was centered left and right

I then placed a scissor jack at the rear of the transmission. I adjusted the scissor jack until my tail output shaft was at zero degrees.

Once I was sure it was level, I zeroed my angle reader then lowered the trans tail by adjusting the scissor jack until my gauge read 2.0 degrees.

I held my trans in that position and tacked my trans mount in place then removed it for final welding.

I didnt go into all the details of measuring overall pinion angle but a quick google search will provide you with the info needed. For me 2 degrees at the trans and diff gave my u-joint an ideal pinion angle.

2003 M5 LSx l 6 Spd Manual l 4.10 LSD

Build Thread

The chassis must always be regarded as a means to an end and never as an end itself

I take a similar approach. I measured the angle of the stock car, then placed the engine and transmission to duplicate that arrangement.

Rob

Prior projects:

1998 540i with 6.6 LS2/T56 Chevy Power

- pictures and details

1992 325i with 6.6 LS2/T56 Chevy power - pictures and details

1995 M3 with 6.6 LS2/T56 Chevy power - pictures and details

Nice build!

When I was making mine, I installed the engine with transmission in the car and mocked up a drive shaft with a 1"X1" wood piece to get my line. I was adjusting transmission with a jack to get it where I wanted to be. Used a level to get it where I wanted. Then I used a plastic pipe with the diamiter of the dirveshaft I was going to use to make sure everything clears.

Once I have my placement I mocked up the cross member out of few pieces of cardboard and then transfered it to steel. I rushed on my cross member a little, and did not make it as nice as I would've wanted though.

Here are few pix from my build

- 96 328is 6.0L. (LS1 to LS2 build thread: http://forums.bimmerforums.com/forum...ad.php?2098938)

- 96 328is 5.7L. (LS1 build thread: http://forums.bimmerforums.com/forum....php?t=1289987)

- 95 ///M3 6.0L. (LS2 build thread: http://forums.bimmerforums.com/forum....php?t=1619249)

- 97 ///M3. (e46 Fender Flares/track car build thread: http://forums.bimmerforums.com/forum....php?t=1727098)

- 96 328is (Dual Fuel Pump to Surge Tank thread: http://www.bimmerforums.com/forum/sh...ad.php?1964025)

Awesome, you guys are great!

Schitzo, I think your method will only work assuming the ground I am working on is perfectly level, right? Is it likely that I will be looking for a 2 degree angle as well since I am a stock geometry (though low ride height) car?

Other problems that occur with engine swaps in the E36 include the driveshaft rubbing the transmission tunnel if the transmission is mounted too high because the driveline angles were "proper."

I almost always figure out the "proper" driveline angle, and then make the crossmember about 1/2" too low, so that shims can be used to adjust the rear of the transmission upwards to accomodate different isolators (stock rubber, aftermarket rubber, or urethane seem to have different heights).

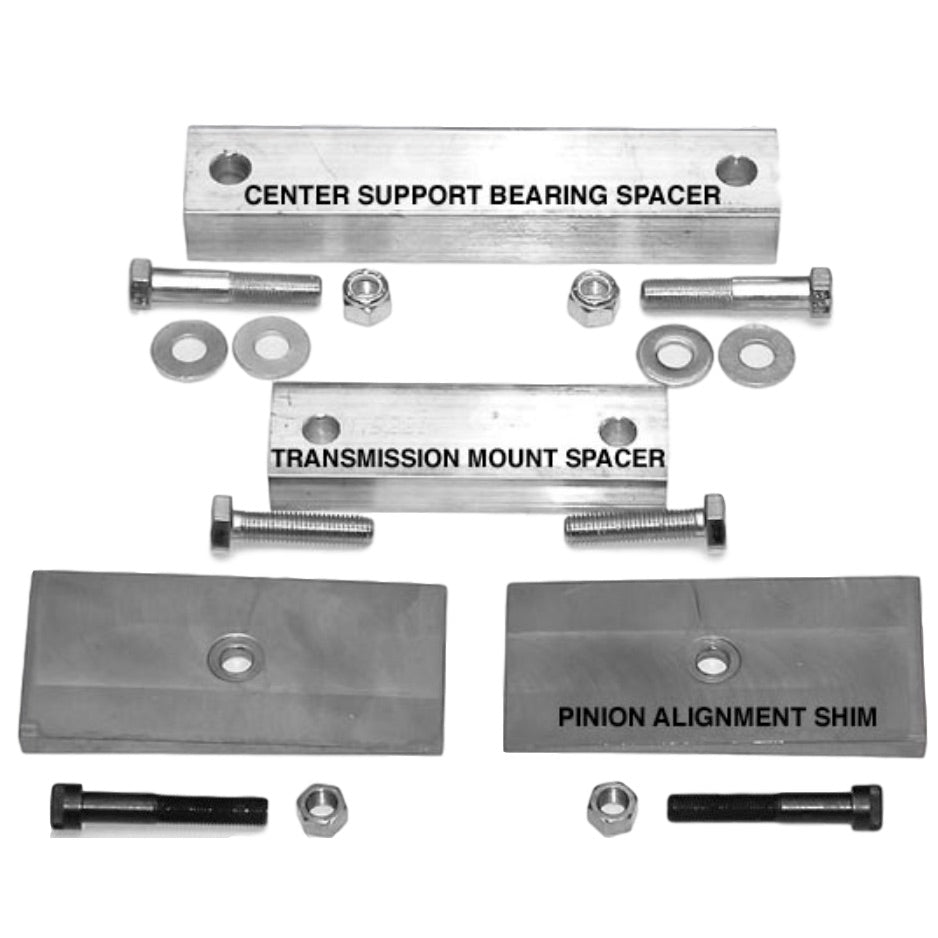

The following picture is a driveline alignment kit we make for the S-10 trucks, but the picture shows the shims for adjusting the transmission height.

We plan on providing transmission mount adjustment shims on the kit we are developing for the E36.

Bookmarks