My arse is fine, it's my knee that's done broke'd up.

Michel, you're on standby, the Migs carry the Exocet missile, they can fire that missile from a hundred miles away, I gotta give you southern hick a dream shot at working on a Yankees' e39, **** Miramar and the Kenny Loggins volleyball, I'm talking about a fly-by on a 2003 525 whose rear end is busted like Kelly McGillis meow during a Righteous Brother's song. Come on Michel, do some of the e39 pilot wrenching sh*t! Grab your 1/2" and 3/4" socket set, fire up the Exocet wheel bearing puller.

"I'd smash that (Jennifer Connelly) like a failed coup in sub-Saharan Africa."

~Macktheknife in my epic Jennifer Connelly OT Thread

Hay Keith,

Did I hear it right? Have you & Gumbi started a self-help group in New Jersey called Suspensions Anonymous? Someone around here was saying you sit around a campfire and sing Kumbaya and recite the Serenity prayer.

Bit far for Jason, though.

HAHAHAHA

G

mmm635,

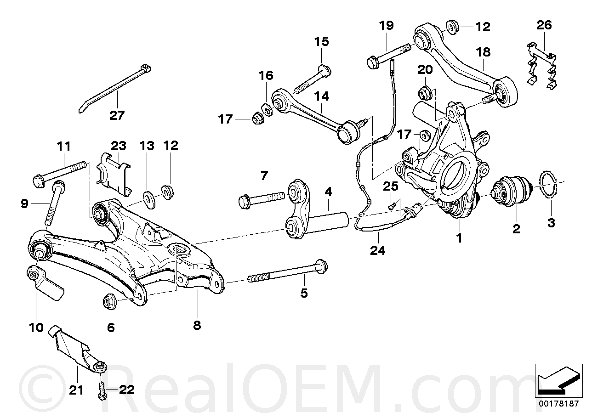

How do you remove Ball Joint Part #2, Any Special Tool for this?

http://www.realoem.com/bmw/showparts...19&hg=33&fg=30

Michel,

Thanks for this post, it was invaluable to me. I got this done last night. I started Tuesday night and worked on it for about 4.5 hours. I struggled with the last bolt holding the bearing in place. This was on my right rear wheel and it was the upper rear e14 bolt. I probably spent an hour trying to get at it and just couldn't get the angle right to get it undone.

I finally started unbolting the upper suspension components. First the shock, no dice! Next the wishbone, nope. The traction strut and finally the integral link to wheel carrier. I still couldn't get at it. At this point I began to wonder if I had pushed the axle far enough in with puller. That 12 ton puller from Harbor Freight is a monster!! It was really hard to get it in place and get it to stay there while pumping it even with my son helping because it is huge and weighs so much! I don't think mine was stuck as much as yours and I should have probably tried a smaller puller I had first, but the sheen of that brand new tool was glinting in my eye and I had to use it.

Anyway, when I put it back on and pressed some more, the axle moved back a lot more and cleared the way to get the last bolt. In retrospect, I might have been able to get the last bolt without unbolting the suspension if I had pressed the axle in far enough in the first place! Then again maybe not!

The bearing came right off the wheel flange, but the inner part stayed on the flange as predicted. I used the same bearing separator that you did and couldn't get under the bearing sleeve and get it off. It was bending the edges of the tool! At this point I decided I was too tired to continue and cleaned up, ate and went to bed. The next morning (Weds) I tried the bearing separator again and used a groove in the sleeve a little higher up to get a grip and it came right off!! Sweet!!

Last night after work I dug back in about 6PM. I had received my parts from Pelican earlier and started putting it back together. I had to remove the parking brake shoes in order to get a good grip on the wheel flange. They just didn't go on like they came off and I had to adjust the cable to get them set right. Everything seems to work OK, but it doesn't seem like I should have had to adjust the cable. I looked at your pics and made sure I got it back together right, so hopefully this won't come back to bite me.

The scariest part of the reassembly was beating the wheel flange back into the bearing. Man it seemed like the bearing was taking a beating and was getting looser. Time will tell. I may have screwed up this part as the axle shaft wasn't coming out far enough to get the nut on so I kept beating. After it was almost all the way on I messed with the axle and it popped though with room to spare to get the nut on! I had tried that earlier, without success, so I don't know. My advice to anyone else doing this is that the wheel flange doesn't have to be that far in to get the axle through, so keep trying to input the shaft in the flange as you go.

I finished last night around 10PM and took it for a test drive and it was the quietest ride I had had for a long time! Success!!! Thanks again Michel for the excellent right up and offer to help!!

Tom

Doin this job over the weekend.

NOTE: My local autoparts store (Advance Auto Parts) rent all these tools:

- Bearing Separator

- Bearing Puller.

Don't buy these tools, just rent them for the job.

1. Spray the area behind the 36-mm nut with WD-40 a few days ahead. This allows the WD-40 to seep into the splines.

2. Many people find it much easier to disconnect the axle at where it connects to the Rear differential. Then gently drop the axle's inner end down a bit. Protect the axle rubber boot with towel. This way when you use a puller to push the axle inward (after the 36-mm nut is removed), it simply pushes the axle inward. Now remove the axle.

NOTE: To remove the 36-mm, car should be on the ground with tires on. Ask someone to step on the brake when you undo the 36-mm nut.

Just loosen the 36-mm nut, then remove it later at appropriate time.

3. This will expose all 4 bolts holding the REAR bearing.

Some useful links:

http://forums.bimmerforums.com/forum....php?t=1225385

This video shows you how to remove an E46 REAR bearing without any special tool (just remove parking brake shoes and place some metal behind it, then use wheel lugs to press it out!):

[ame]http://www.youtube.com/watch?v=wKYL9_4mXRI[/ame]

Last edited by cnn; 03-11-2011 at 11:45 AM.

Good info Cnn!

Thanks!

I will rent these tools!

Thanks!

Jason

Looking for an E39 belly pan , passenger front inner fender liner …

WOW

this is cool

THE BOLT METHOD a ??

something similar i used for front trust arm bushing

http://forums.bimmerforums.com/forum....php?t=1312454

Last edited by champaign777; 03-11-2011 at 01:59 PM.

I just completed this job on my '99 528iT (160K miles, non SLS) and it was a real b!tch. But made less so by the telephone technical support graciously provided by Michel (AKA mmm635). I must say that the improvement is nothing short of dramatic. It is like a completely different car. In my case the passenger side bearing was the culprit, but I replaced both sides.

I have a few observations I would like to share with anybody considering doing this job.

None of my local auto parts stores (Autozone, Advance, O'Rielly's) had a bearing separator in their loaner tool inventory. It's not that they didn't have one available, they didn't have them AT ALL. So I tried to do the job without it. Not recommended! This job is nearly impossible to do without it. I checked with every store I could think of and nobody had one. So I made the hour-long round trip to the nearest Harbor Freight and bought this one for $30:

http://www.harborfreight.com/large-b...ator-3979.html

They had this one, along with a bearing removal kit that contains two different sized separators - both smaller than this one. I chose this one because it will be serving double duty and the bigger size is helpful.

While I was there, they also had a 2 ton low profile jack on sale for $80. This is a very nice jack with a range of 3" to 20". It sure beats the wimpy aluminum racing jack I had been using. Getting the car up as high as possible is essential and this one got the car a full 6 inches higher than I could before.

There is a trick to getting the wheel hub out of the bearing using the bearing separator. This method works very well, is relatively easy, and best of all, avoids the alarmingly explosive sudden release that mmm635 experienced when using the hydraulic puller.

Remove all the parts of the parking brake, then place the bearing separator behind the hub. Thread in a couple of wheel bolts and tighten them against the body of the separator. This will gradually push the hub out of the bearing. The lugs will not be long enough to push the hub all the way out, so you'll need some kind of shims. I have a disc brake service kit that includes several metal plates and discs in various thicknesses. Using combinations of those worked well for me. When the hub comes out of the bearing, it will just fall out - instead of flying across your garage!

Once you have the hub out, the inner race of the bearing will come with it. This is where the bearing separator really comes in handy. There is no need to heat, beat, cut, and curse the bearing off and risk damaging the hub. The particular separator that I bought had "blades" that were a little too thick to get under the edge of the bearing and really bite into it. The tool doesn't seem to have very tight manufacturing tolerances and I don't know if they are all too thick or if it was just mine. I used a grinder to sharpen the blades and that did the trick. Once the separator is in place and tightened, use the wheel bolts again to push the bearing race off the hub. Again, shims will be needed. It took me about 10 minutes per hub to remove the bearing. The tool is definitely worth the money and was worth all the trouble I had in finding it.

To get to the 4 torx bolts holding the bearing assembly to the wheel carrier, I was able to lie on my back under the swing arm to access them. With the bearing removed, the drive axle can be moved around and I just moved it out of the way for each bolt. I did not remove the drive axle from the car. It's also not necessary to disassemble any of the suspension parts. This is where a good floor jack is helpful. Getting the car as high as you can makes it much easier to work. And of course, use good jack stands! For an extra measure of safety, I also laid the wheels on the ground under the car. So at least if it did fall somehow, it wouldn't go all the way to the ground!

Start to finish, this job took me a solid 20 hours. But 3/4 of that was spent on the first bearing just figuring out what to do and fumbling with the wrong tools. The second bearing when MUCH quicker and I could probably do the whole job in about 5 hours now that I know what to do and what tools to use.

Thanks again to Michel for creating this thread, and for helping me out directly.

1998 ///M3/4/5 | 1999 528iT | 2003 Z4 3.0i

BimmerM3in GA,

You say the difference is dramatic. What were your specific symptoms that drove you to do this repair?

KP

"I'd smash that (Jennifer Connelly) like a failed coup in sub-Saharan Africa."

~Macktheknife in my epic Jennifer Connelly OT Thread

A very loud WAH WAH WAH sound at all speeds - worse and louder as speed increased and a rear end vibration. I thought it was my tires and after replacing all four tires and installing new Bilstein struts/shocks the sound and vibration was still there. Both are now gone and the car drives much better.Originally Posted by bimmerfiver

1998 ///M3/4/5 | 1999 528iT | 2003 Z4 3.0i

Another poster asked this but never got a reply.

When are people replacing these things and why? Any certain years have more troubles?

I now just rolled over the 193k mark and to my knowledge the wheel bearing have never been touched. It is a 97 540i so I might be due but I don't BELIEVE I have have any symptoms of them going bad.

There isn't really a defined replacement interval. It really depends on how the car is treated. If you always drive on smooth and straight roads, your bearings will last much longer than if you like to catch air going over railroad crossings.

If you don't have any symptoms, there is no need to replace them until they start showing signs of going bad. There is plenty of warning to replace them. They aren't like a plastic radiator that can suddenly and catastrophically fail without warning, leaving you stranded.

Mine have been bad for at least six months and I continued to drive on them. The most common warning sign is a WAH WAH WAH sound coming from the rear of the car. Watch the video linked in post #57. You can clearly hear the sound the bearings make.

1998 ///M3/4/5 | 1999 528iT | 2003 Z4 3.0i

Guys, how did you manage to set up the HF 12-ton puller to push the axle out? The jaws are way are too long and the shaft is too short (even fully extended it doesn't even touch the tip of the axle). Did you put something between the axle and the puller shaft to compensate? Thanks!

I've seen this picture, but that isn't the HF hydraulic puller, is it? Below is what it looks like for me. As you can see the jaws are at the lowest position and the shaft is fully extended.

I'm thinking of drilling extra holes in the jaws for lower positions, but is this what you guys used? Or did HF change the design of the item?

Last edited by jvfff; 05-24-2011 at 10:05 AM.

I've just done some searching and it appears that they replaced the puller with a different model.

Here's the new one: 12 Ton Hydraulic Gear Puller Item #66657

And here's the old one: 12 Ton Hydraulic Gear Puller Item #95122

mmm635, when I looked at your picture I assumed that it's some other puller since it looks nothing like the one I just got under the same name.

I usually get lucky with HEAT.

Just use Propane Torch (the same stuff plumber uses for soldering copper pipe), about $10 at hardware store.

Just apply 15 seconds of heat on the Hub part that goes around the Axle. The idea is to expand the hub.

Don't heat the axle end, just the hub round part so it breaks up any rust/bonding material.

Also this expands the hub a fraction of a millimeter, enough to use a standard 2-ton puller.

The HEAT trick works great for 20 years for me in all kinds of different cars, from Honda to Volvo etc.

Last edited by cnn; 05-24-2011 at 11:26 AM.

If you have air tools, then Bimmerfiver's method/ thread might help...:

http://forums.bimmerforums.com/forum....php?t=1655396

Looking for an E39 belly pan , passenger front inner fender liner …

Thanks guys! Great advice, I'll try heating first since I have all the tools for that method.

Curious why HF discontinued that 12-ton puller, seems to be better then the new one in several ways...

I did try yesterday to adapt the 12-ton puller by using a steel bolt between the axle and the puller's shaft and ended up literally splitting the bolt in half and the axle didn't show any signs of moving. I also got the 5-ton version of the puller, that one does reach the axle fine, but seems to be "skipping" after a certain amount of tension applied. I wonder if the tool is defective or did I actually reach the 5-ton limit and the safety kicked in.

Last edited by jvfff; 05-24-2011 at 04:49 PM.

Try using a slide hammer, like what Bimmerfiver used in his thread, post#1, 2nd picture:

http://forums.bimmerforums.com/forum....php?t=1655396

Looking for an E39 belly pan , passenger front inner fender liner …

Slide puller.

No heat.

No PB Blaster.

25-30 hard yanks and it came off.

Both sides.

And that's 140K New York salty-winter drives.

On ESPN2 when they have those lumberjack contests with rednecks running around with chainsaws, then next station for a pull saw etc? You put me in one of them with e39 rear axles instead of trees/wood and a Snap-On slide puller.

I did both sides in just over 2 hours. Having a lift was huge. Having an air-grinder and air-chisel was the key once the spindle was out.

"I'd smash that (Jennifer Connelly) like a failed coup in sub-Saharan Africa."

~Macktheknife in my epic Jennifer Connelly OT Thread

Bookmarks